Screen printing is a versatile and traditional method in textile printing that has advanced over the year to become an art form and a practical solution for creating vibrant and durable prints on various fabrics, Without losing quality screen printing can print bulk numbers of clothes like Jerseys, T-Shirts, and many different kinds of products in a matter of time. We will explore all the aspects of screen printing in this blog post. So, whether you are a newbie or a enthusiast, there are many things you can learn in this blog post.

- What is Screeseasoned textilen Printing?

- History of Screen Printing.

- Things to Check Before Screen Printing.

- Process of Screen Printing.

- Things to Remember Before Purchasing Screen Printed Products.

- Types of Screen Printing.

- Difference Between Screen Printing V/s Other Printing Methods.

- Advantages and Disadvantages of Screen Printing.

- Will Screen Printing Washout.

- Fabrics Used in Screen Printing.

- Screen Printing Latest Trends 2023.

- List of Best Affordable Machines for Screen Printing.

- Other Products That Can be Used in Sublimation Printing.

- Where to Get Your Screen Printed Products.

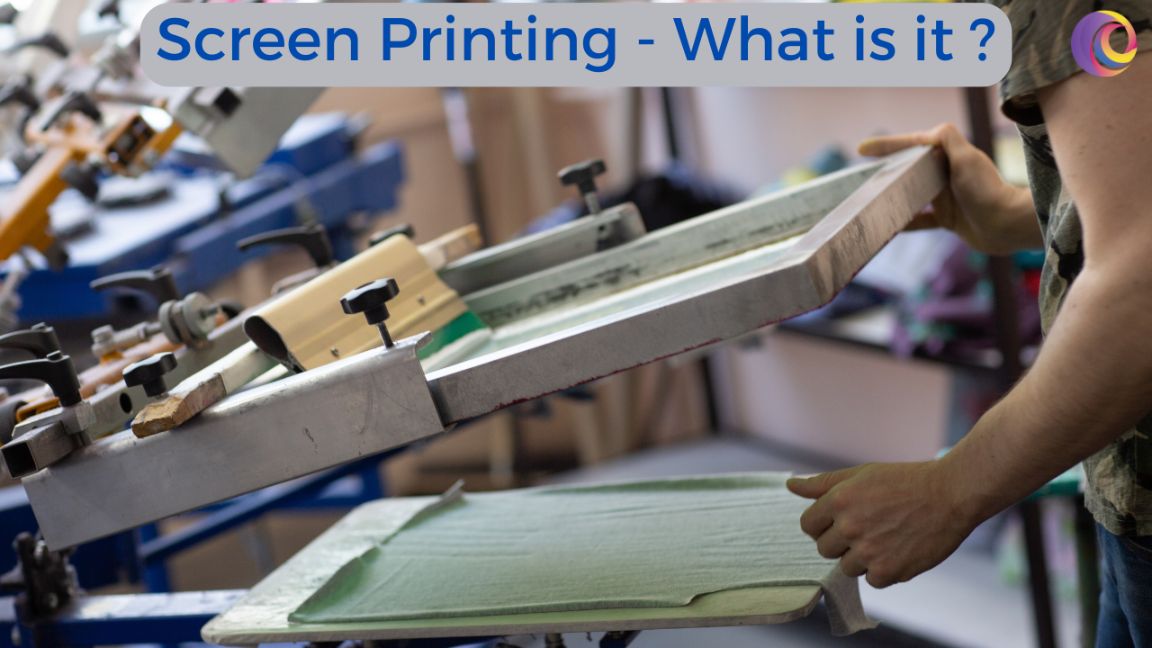

What is Screen Printing ?

Screen printing which is also popular as silk screening and silkscreen printing in many parts of the world. In simple words screen printing is a method that include transferring ink onto a solid substance such as fabric through a mesh screen. All the different colors in designs demands a dedicated screen, which makes it best for complex and multicolored designs. These elements ultimately make screen printing best options to produce vibrant and long lasting prints.

History of Screen Printing.

Screen printing has a vast history, after all, it is the first printing method in the world. So let’s start from the beginning. Screen printing originated in ancient China during the reign of the Song dynasty during 960–1279 AD, At that time stencils were used to transfer ink onto fabric. There are many traces that confirms that during the 10th century screen printing is widely used to create complex designs on cotton fabrics in India, especially in the state of Gujarat.

With time, screen printing started its global journey. In 18th century Japan, artists converted this textile printing technique into a way to showcase their artistry. Simultaneously the West, silk printing made its presence felt in Europe in the 19th century. The biggest reason behind its gaining popularity in major parts of the world is that silk printing is an effective method, especially for complex design patterns as compared to other methods.

The 20th century witnessed the biggest turning point for Silkscreen printing because of the Industrial Revolution, which eventually became a reason behind technological progress another change that happen during this time period is that silk screens are adapted as a fundamental component of the printing process and become the reason behind screen printing also get famous as “silk screen printing”. In 1907 Samuel Simpon patented a method of screen printing using a rubber blade, which become one of the biggest improvements in screen printing technique.

As I said earlier 20th century is the most important century for silkscreen printing. As the 20th century matured screen printing became a powerful tool in the world of pop culture and commercial art. During the 1960s and 70s screen printing was extensively used in printed posters focused on countercultural movements that celebrated artistic expression. Famous celebrities like Andy Warhol brought screen printing into the limelight.

The invention of Computer-aided design influenced silk screen printing significantly. Artists and designers picture complex designs with flawless execution. Digitalization of screen printing propelled it into a new era of creative possibility.

In the present day, screen printing continues winning the hearts and minds of people who love customized products as well as artists who use their art to talk world rather than words.

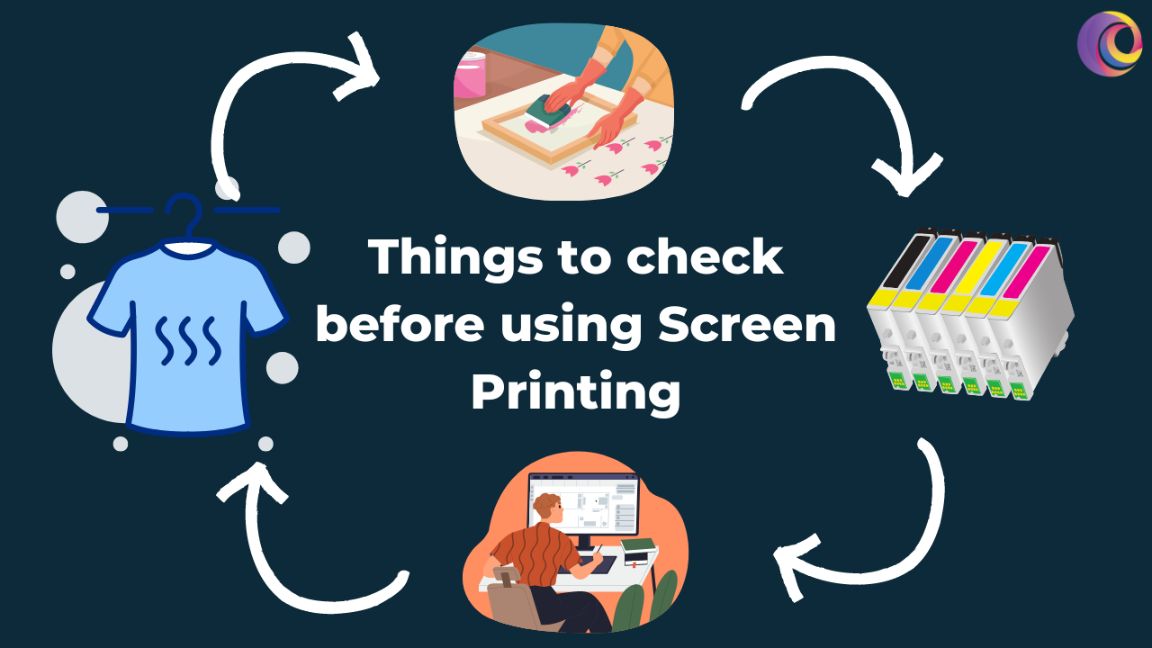

Things to Check Before Screen Printing

Creating a high-quality customised product is like a mission, and in order to complete this mission you must have a plan. So, here are important checkpoints to navigate before creating silk screen printed products :

Design resolution in screen printing

The soul of a successful screen print depends on design resolution. To achieve sharpness and clarity you must ensure that your design is made of high resolution, if the resolution has any kind of inconsistency it will downgrade your end creation with blurry and pixelated prints. Don’t hurry, take your time because a good start can enhance your confidence for further steps.

Color separation in screen printing

Complex and multicolored print need great attention to detail during color separation. Every hue requires a dedicated stencil layer and correct separation to maintain color accuracy. Muddy color and lackluster prints are the result of inaccurate separation. Use design software or get assistance from a professional (if necessary).

Fabric compatibility in screen printing

Different fabrics suited some specific inks. Understand the combination between fabric and ink to ensure a seamless bond. For example, Water-based inks are a good choice for light-colored fabrics. prioritize ink compatibility, tailoring your choice to the fabric’s characteristics, be it stretch, fabrics GSM, or weave.

The screen quality of screen printing

The fidelity of your print totally depends on the screen’s soundness. Completely check the screen printing for imperfections like pinholes or tears, which can spoil the final design. A flawless screen helps the ink flow smoothly through the stencil which ultimately creates the perfect print. So always use high-quality print and maintain it by taking care of it.

Preparation for screen printing

Sufficient preparation is the key to achieving ink stickiness and durability. Treat the fabric wisely to eliminate sizing, oils, or contaminants that block ink absorption. It helps in offering vibrant colors and lasting impressions.

With the help of these checkpoints, you became confident to embark on the screen printing journey.

Process of Screen Printing

When technique and creativity create a bond through harmonious dance, as a result, the design comes to life through ink, mesh, and precision. Now we are going to learn about some important steps to keep in mind while screen printing. If you are starting your screen printing bussines in clothing line than you must remember this point.

Step 1 –

Design creation and preparation for screen printing

Crafting quality design is the first step in this journey. For your aimed silkscreen printing this design serves as the blueprint. Make sure the design is high-resolution, captivating, and aligned with your artistic vision. A high-quality design gives you a lot of confidence which helps in your upcoming journey during this process.

Step 2 –

Stencil creation in screen printing

The design transformed into a stencil which defines the route through which ink will flow. In the canvas, a mesh screen is covered with light reactive emulsion. The position is the design of acetate assembly on the top of the emulsion-coated screen and then exposed to intense light. Eventually light solidifies the emulsion preserving areas untouched by design.

Step 3 –

Stencil development in screen printing

After a specific duration wash out unhardened emulsion which has been exposed to the light. The result is a stencil, a roadmap for ink transfer. The mesh screen act as a gateway, guiding ink to the substrate beneath, intricately recreating the contours of your design.

Step 4 –

Fabric preparation in screen printing

We all know that fabrics are one of the most important factors that can change your print quality upside down. Pre-treat the fabric carefully, and eliminate impurities that hinder ink adhesion. Make sure the fabric surface is pristine.

Step 5 –

Positioning the screen of screen printing

Align the prepared screen atop the substrate, ready to breathe life into your design. Whether using a manual, semi-automatic, or automatic press, secure the screen in place. This platform ensures stability, enabling precise ink transfer.

Step 6 –

Applying the Ink during the screen printing process

When you are done with positioning the screen, now add the ink to the equation. Transfer the ink of your chosen hue. apply a squeegee (a tool with a rubber blade attached to the handle) to draw the ink across the screen’s surface. This step helps to press the ink through the open areas of the stencil, imprinting the design onto the substrate beneath.

Step 7 –

Lift and repeat during the screen printing process

Now, here we go lift the screen to reveal the masterpiece beneath. In the case of multiple items, the process repeats each lift and press creating a replica of your design.

Step 8 –

Ink curing during the screen printing process

Printed substrate embarks on a journey through a dryer, a vital step that cures the ink. The application of heat solidifies the ink resulting in a vibrant, colorfast finish that withstands the test of time.

Step 9 –

Inspection and finishing of screen printing

As the ink settles into a permanent place a meticulous inspection ensues. Make sure all designs are flawless and the hue resonates with brilliance. Once approved, the printed product undergoes washing to remove lingering residue, preparing it for a new role as an artistic statement.

From design inception to final print inspection, screen printing transforms an idea into an enduring masterpiece that resonates with viewers and stands as a testament to the art of transformation through ink and mesh.

Things to Remember Before Purchasing Screen Printed Products.

As you embark on a journey to acquire screen printed products that exude artistry and individuality, a thoughtful approach becomes the compass guiding your choices. Whether it’s clothing, accessories, or home décor, here are essential factors to remember before indulging in the allure of screen printed treasures :

Quality Is Paramount in screen printing

Before making a purchase, prioritize quality. Examine the fabric, stitching, and overall craftsmanship. A well-crafted item ensures longevity, allowing your chosen design to remain a captivating statement piece.

Design Authenticity in screen printing

Delve into the backstory of the design. Is it an original creation or a reproduction? Authenticity adds a layer of value to the piece, making it not just a possession, but a reflection of the artist’s creativity.

Artistry and Detail in screen printing

Screen printing is a testament to artistry. Pay attention to the intricacies of the print—the sharpness, color vibrancy, and attention to detail. A carefully executed print enhances the visual impact and transforms a product into wearable or displayable art.

Fabric Compatibility in screen printing

Different fabrics interact with screen printing in distinct ways. Research the fabric type to understand how well it accommodates the ink. Ensuring that the fabric is compatible with the chosen ink guarantees lasting brilliance and comfort.

Sustainability Considerations in screen printing

In an era of eco-consciousness, inquire about the product’s sustainability footprint. Are eco-friendly inks used? Is the fabric sourced responsibly? Opting for environmentally conscious products aligns with your values and contributes to a greener future.

Customization Possibilities in screen printing

The allure of screen printing lies in its customization potential. If desired, inquire about customization options. Personalized screen printed products offer a unique touch, making them not just items, but expressions of individuality.

Artist Recognition in screen printing

Screen printing often involves collaboration with artists. Research and acknowledge the creative minds behind the designs. Supporting artists fosters a connection to the creative process and elevates your ownership experience.

Size and Fit in screen printing

For clothing, consider the size and fit. Ensure the product aligns with your preferences, offering comfort and confidence. A well-fitting item becomes an extension of your style and identity.

Care and Maintenance in screen printing

Understand the care instructions for the product. Proper maintenance ensures the longevity of the screen printed design. Follow recommended washing and care guidelines to preserve the artistry. Remeber T-Shirt and Hoodies are have different care and maintaince guidlines.

Pricing Transparency in screen printing

Transparency in pricing reflects a commitment to ethical business practices. Evaluate the pricing in relation to the product’s quality, craftsmanship, and the effort invested in the screen printing process.

Embrace the Story in screen printing

Every screen printed product carries a story—of the artist, the design process, and the creative journey. Embrace this narrative as you make your selection, connecting with the essence of the piece beyond its physical form.

With these considerations at the forefront, your journey to acquire screen printed products becomes a curated experience. Each item you select not only embellishes your life but also forms a tangible connection to the world of artistry, technique, and expression. As you explore the vast array of screen printed treasures, remember that your choices reflect not just possessions, but reflections of your discerning taste and appreciation for the intricate world of screen printing.

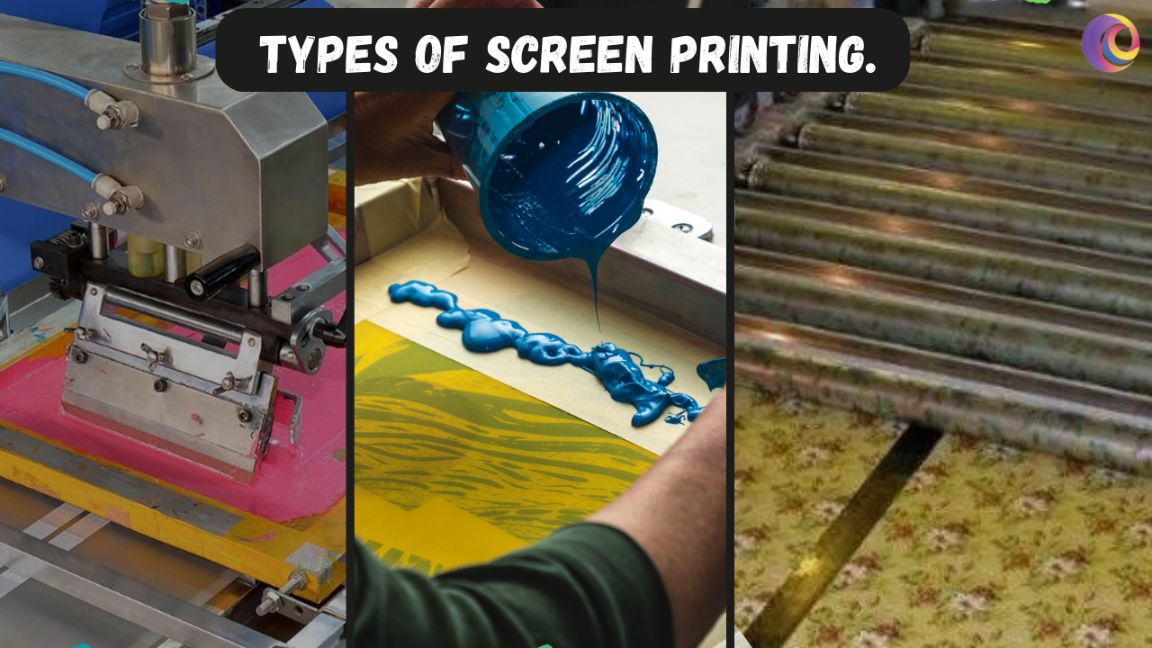

Types of Screen Printing.

Screen printing is a very universal form of art its technique caters to various needs and aspirations. All methods have a separate approach with different materials, effects, and levels of complexity. Let’s talk about these techniques.

Standard screen printing

This single screen is used to apply a single color onto the substrate. It’s a simple and straightforward method best for simple designs and smaller quantities. For those who are looking for a classic and clean look and has no experience in screen printing, this method is for you.

Multicolor screen printing

As the name suggests, multicolor screen printing involves using multiple screens, each dedicated to a specific color. The screens are aligned precisely to the layer colors, creating complex and vibrant designs.

Plastisol screen printing

This technique is versatile, vibrant and creates opaque prints on various fabrics. Plastisol ink is the star of the technique. This ink remains in a liquid state until heat cured which eventually makes it the best choice for detailed designs and color gradients. This technique also helps print in durability.

Water-Based screen printing

If you are conscious about the environment and searching for eco-friendly options, then water-based screen printing should be your silk screen printing technique. It connects with fabrics and creates a soft and breathable feel. It is best for lighter fabrics because it doesn’t add texture weight.

Discharge screen printing

The discharge technique is like a cousin of the water-based technique. In this technique, a special ink removes the dye from the fabric, creating a bleached effect. This technique is best for achieving soft, complex prints on dark fabrics.

Metallic and foil screen printing

For a luxurious touch, metallic and foil printing is best. Metallic ink is used as creating a shiny and gives a metallic finish, on the other hand, foil sheets are heat pressed onto the substrate which eventually results in a reflective and captivating effect.

High-Density screen printing

For tangible impact, high-density printing enters the scene. In this technique, extra thick layers of inks are applied to specific areas of designs which creates a raised and textured effect. This technique adds dimension which enhances the visual and tactile experience

All-Over screen printing

All over technique is kind of newest technique which breaks the limit of traditional technique. In this method, you can design the print all over the fabrics. All techniques are mostly seen on the garment like T-Shirt , with bold immersive effects that capture attention from every angle.

Digital screen printing

Merging the digital and screen printing worlds, this technique employs digital printers to create stencils. It allows for intricate designs and multicolor prints, merging the precision of digital technology with the tactile beauty of screen printing.

Difference Between Screen Printing v/s Other Printing Methods

Till now we are learned many things about screen printing. But we are going to cover that point which is probably the most common question among custom product seekers and custom product makers that is “What is the difference between screen printing and another printing method?”. so let’s go.

Screen Printing vs. Digital Printing

As I told you beginning silkscreen printing methods involve using stencils and ink to imprint the design onto the surface of fabric and other products. In contrast, digital printing employs specialized printers that transfer designs directly onto surfaces. It outshines in producing intricate multicolored designs in less time. Silkscreen printing offers durability which automatically made it best for long-lasting designs on fabric, paper, and even metal. Digital printing is swift it may not match silkscreen printing longevity on surfaces.

Screen Printing vs. Heat Transfer Printing

Heat transfer depends on heat transfer design from a carrier paper onto the substrate. This method is flexible for small runs but can be prone to cracking and fading over time, especially on fabrics subjected to frequent washing. While on the other hand silkscreen printing is known for its vibrant and ability to create complex designs also it is particularly well suited for bulk orders and items that demand a longer lifespan

Screen Printing vs. Sublimation Printing

The sublimation printing process includes transferring ink onto the material using heat. its process is very different from the silkscreen printing process. In some manner, sublimation printing has similarities with silkscreen printing sublimation printing methods are also well suited for complex and full-color designs on polyester fabrics, but do not give the same level of vibrancy on other materials. Screen printing creates designs with rich, opaque colors that are vivid and long-lasting. It’s a versatile technique suitable for a wide range of substrates, including fabrics, paper, and more.

Screen Printing vs. Embroidery

The method of embroidery involves stitching thread directly onto fabric in order to create fabric designs. Embroidery is best for a tactile feel and is particularly popular for branding on garments like caps and jackets etc. This method is very different from silkscreen printing in the case of process, designs, elements, and also with results.

Screen Printing vs. Direct-to-Garment (DTG) Printing

Direct-to-Garment (DTG) uses inkjet technology to print designs directly onto fabrics. It’s suitable for complex, full-color designs and offers a soft feel, however, it may not provide the same level of longevity on the fabrics as silkscreen printing do.

Screen Printing vs. Block Printing

Block printing involves carving a design into a block and then stamping it onto fabric or paper. It offers a distinct handmade aesthetic but may be limited in terms of design complexity and color variation.

Advantages and Disadvantages of Screen Printing

When it comes to the advantage and disadvantages of silkscreen printing than silkscreen printing has two sides just like a coin. So let’s take a look at both pros and cons of silkscreen printing.

Advantages of Screen Printing –

Vibrant and durable

Silkscreen printing has the ability to create dynamic and bold colors that live over time. The quality of ink allows designs to pop on both light and dark substrates, ensuring lasting visual impact.

Versatility of substrates

silkscreen printing is known for its versatility, from fabric and paper to metal and glass, screen printing beautifies an array of materials. Its adaptability lends itself to diverse applications, including clothing, signage, art prints, and more.

Complex details

The technique’s accuracy enables the replication of complex details and complex designs. from lines to gradient shades, silkscreen printing captures shades that bring artistry to life.

Longevity and resilience

Resilient screen printing tolerates the test of time and regular use. It remains vibrant and unbroken making it an ideal choice for products that endure long wear.

Cost-Effectiveness in bulk

In the case of larger quantities silkscreen printing glow as a cost effective choice. Once screens are set up, reproducing designs becomes efficient and affordable.

Customization potential

Customization succeeds with silkscreen printing, allowing for variations in colors, sizes, and designs. This versatility catches attention to both individual preference and brand needs.

Aesthetic appeal

The tactile quality of silkscreen printing lends a unique charm. The ink sits atop the substrate, offering a visual and textural allure that distinguishes it from other printing methods.

Disadvantages of Screen Printing –

Setup complexity

Silkscreen printing demands a complex setup. It involves stencils, screens and multiple layers of ink, etc. This complexity can discourage those who want quick, single-piece prints.

Limited color blending

As we know silkscreen printing offers vibrant colors but there are very high chances that color blending can be challenging during vibrant color designs because each color requires separate screens.

Time-consuming for multicolor

In the case of multicolored designs, screen printing can be time demanding. All color desperately needs a separate pass which automatically extends the production timeline.

High initial costs

The cost factor is very objective in silkscreen printing. As I told you in the advantage section in the case of bulk orders screen printing is very cost-efficient but if we see from the perspective of the initial cost of setting up screens and equipment then making screen printing is less achievable for smaller quantities.

Not good for fine art prints

On the one side silkscreen printing is best for graphic designs but on the other hand, it might not capture the shade and texture required for certain fine arts prints.

Limited print size

Screen sizes affect results in many ways, one of the biggest negative results of screen sizes is they restrict on the size of the prints. Of course, large-scale design might require multiple screens which increases the cost.

Not suitable for small text

In some cases, small text or complicated details might not export well due to the limitation of screen mesh.

Where to Get Your Screen Printed Product

Get the ultimate destination for all your custom jersey needs – Custombaba As a premier custom clothing manufacturing company based in Ludhiana, India, Custombaba specialized in bringing your jersey visions to life with matchless craftsmanship and versatility.

Why choose Custombaba :

Wide Range of Customization

At Custombaba, we believe in the power of personalization. Our extensive range of customization options ensures that every jersey we create is a true reflection of your style, team identity, or brand message we have Custom T-Shirt , Custom hoodies , Custom jerseys , Custom sipper , custom bags and much more. From fabric selection to design intricacies, we’ve got you covered.

Expert Design Team

Our team of experienced designers team up closely with you to craft designs that captivate. Whether you’re aiming for a classic look, a modern edge, or something entirely unique, our designers transform your ideas into stunning realities.

Quality Beyond Compare

We’re committed to delivering excellence. Our use of premium materials and state-of-the-art printing methods ensures that each jersey not only looks exceptional but also feels comfortable and endures wear and tear.